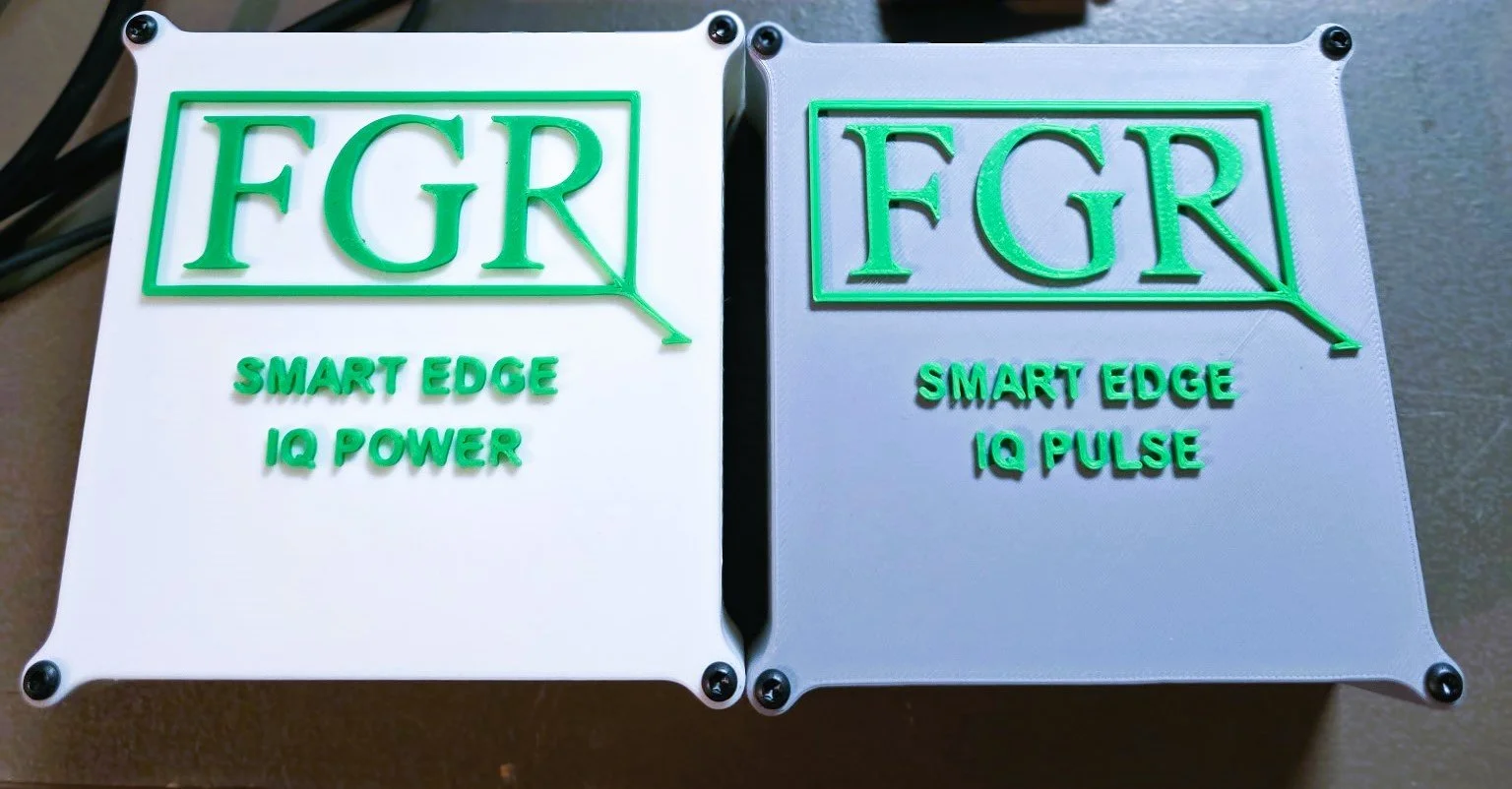

Smart Edges for Power Monitoring and Machine Monitoring Analytics these can be accessed directly via web browser or via supervisory Smart Edge

SCADA Versus IIoT Industry 4.0

The main difference in features between SCADA (Supervisory Control and Data Acquisition) and IIoT (Industrial Internet of Things) systems lies in their architecture, data handling, and scope of application, which reflect their distinct purposes in industrial environments. Below, is a summary of the key differentiating features for context and clarity.

Main Difference: Centralized Control versus Distributed Intelligence and Scalability

SCADA: Primarily focuses on centralized real-time monitoring and control of industrial processes. It collects data from field devices (e.g., sensors, PLCs) via wired or limited wireless connections, processes it on-premises, and presents it through a human-machine interface (HMI) for operators to make immediate decisions. SCADA excels at supervisory control for specific processes, such as adjusting machinery or responding to real-time alerts, but it is often monolithic, with limited scalability and interoperability due to proprietary protocols and data silos.

IIoT: Emphasizes distributed intelligence, scalability, and advanced analytics by connecting a broader network of smart devices (sensors, actuators, machines) over the internet, using premise or cloud-based platforms. IIoT collects diverse data types, supports wireless connectivity, and leverages big data analytics, AI, and machine learning for long-term process optimization, predictive maintenance, and cross-system integration. It uses open standards and APIs for greater interoperability, making it more flexible and scalable than SCADA.

Key Feature Comparison

SCADA: Its core feature is real-time supervisory control with a focus on immediate operational adjustments (e.g., controlling a valve in a water treatment plant). Data is typically processed locally, and its historian component stores limited historical data for short-term analysis.

IIoT: Its standout feature is data-driven optimization through cloud-based analytics, enabling predictive maintenance and trend analysis across distributed systems. It handles large datasets, supports server-less architecture, and integrates with enterprise systems for broader insights.

Practical Implications

SCADA is best for localized, real-time control in industries like manufacturing or utilities where immediate response to process changes is critical. However, it struggles with integrating diverse devices from different vendors and scaling across large, distributed operations.

IIoT shines in scenarios requiring scalability, remote access, and advanced analytics, such as predictive maintenance in a diverse variety of industrial machines and processes or for optimizing QC and infrastructure and supply e.g. Electric Power Consumption & Quality.